FAQ

Below you can find some frequently asked questions about Partanna, our technology, our products and their availability worldwide.

What is Partanna?

Partanna Global is the visionary holding company that oversees the operations and innovation that breathe life into our core mission.

Where is Partanna located?

Partanna Global is registered in Delaware, United States. We currently have two affiliates: Partanna Bahamas, registered in Nassau, The Bahamas, and Partanna Arabia, registered in Saudi Arabia.

When was Partanna created?

Partanna Global, Inc. was founded in 2021 by Rick Fox and Sam Marshall. However, the path to innovation began as way back as 2015, when Sam began his search for a building material that could do more than conventional materials.

What’s your plan to change the way the world builds?

Partanna’s vision is broad – but at a high-level, we wish to move the construction industry away from its current model – where human development comes with a heavily pollutive price.

Through our innovation, we are demonstrating that the world does not require Portland cement to get to concrete. We are proving that other – more sustainable and cost-effective – options are available, that don’t cost the earth or the Earth.

Our initial plan to expand accessibility to our materials and technology is to establish factories globally to meet demand. We are currently planning to build facilities in The Bahamas, the USA, and the Gulf region. At this stage of our business, we remain open to investment or collaboration with individuals or organizations who have the capital or resources to open factories in new territories.

Once we have proven our operating model at scale, our vision is to work with franchise or licensees who can help bring Partanna to the world.

Longer-term – our R&D teams are targeting other new technologies that offer an alternative and more sustainable path to the construction industry’s most common materials.

Is Partanna seeking investment?

Partanna welcomes conversations with individuals and entities that share our mission and have the resources to support the accessibility and reach of our technology globally. Those looking to expand Partanna into a new market that is not currently in the scope of our short-term business plan must provide capital for the cost of establishing manufacturing facilities and other operating costs.

Why isn’t Partanna currently licensing its technology?

We are preparing the groundwork for a future where we do. Our focus right now is meeting the demands and needs of our visionary customers who are looking to build with us at scale.

What supply-chain solutions is Partanna seeking?

As our business expands globally, we are seeking partnerships with individuals and entities that can help us secure raw materials, forge offtake agreements, and expand our brand in new territories.

What talent is Partanna seeking?

We are actively looking for new teammates that can help us fulfil our mission and bring Partanna to the world. All live roles are advertised via our website – but we welcome applications and introductions.

I’m a developer. How can I build with Partanna?

Right now we have modest manufacturing facilities in California that produce tiles.

In 2024, we’re planning to establish manufacturing facilities in the US, The Bahamas and The Arabian Gulf.

We launched our business in November 2022 and have ambitious plans to build out our operations globally.

Right now – if you’re interested in bringing Partanna to you today, the quickest route is via a JV for a factory. If that’s something you’re interested in, and can commit the cost of capital, please reach out.

Otherwise, if you’re able to commit to the long-term factory offtake from a factory, via a purchase order – we’re also open to a conversation.

I’m an existing concrete manufacturer. Can I license Partanna?

Unfortunately, licensing isn’t in our short-term plans – we’re preparing the groundwork for a day when we are able to offer this.

How does Partanna’s technology work?

At a high-level – we negate the need for Portland cement by leveraging an alternative binder made from two recycled materials – brine and steel slag.

With Partanna, there’s no need for heating or the clinkering process – our process is performed at ambient room temperature.

Once brine is added to our mix, the reactions and curing process creates chemical compounds that react with carbon dioxide in the air.

As the CO₂ dissolves into our mix, it helps create a novel type of binding agent that essentially serves the same purpose as traditional cement.

What happens to the CO₂?

As it reacts, it changes form. In short – it’s not coming back out into the atmosphere – unless you decide to heat our products at crematorium level temperatures. But why would you want to do that?

What materials does the company use?

Unlike traditional concrete, which requires ingredients produced solely for its production and emits significant amounts of carbon, Partanna is made using recycled waste materials, such as steel slag and saline solution.

Both of these components are widely available in many markets. Steel slag is a by-product of the steel manufacturing process and is generated in large quantities globally. Brine is produced as a waste product by many desalination plants, which are becoming increasingly common in areas where freshwater is scarce.

I’ve seen other “sustainable concrete” brands. What makes Partanna different?

At a very high-level – there are two types of innovation in the low-carbon concrete space.

The first category of innovation involves the continued utilization of Portland cement as a binder. However, some companies seek to offset or avoid the emissions associated with cement by performing the clinker production process with renewables. Others use CCUS (Carbon Capture Utilization and Storage) technologies that involve capturing CO₂ via an industrial process before transporting it and then finally injecting it into their mix. Both are wildly imperfect technologies that are inefficient and at best, lead to a slightly ‘less bad’ concrete.

The other category of innovation is the alternative binder space. That’s where Partanna sits, as we replace the need for any Portland cement in our mix. There are currently a number of other companies who claim to have identified alternative binder solutions, but we are not aware of any that are close to being commercially scalable globally and that can achieve the level of impact that Partanna can. Moreover, our use of brine means that we can also negate the environmental impact of this waste material, and that our products – uniquely – become stronger when exposed to seawater.

What can you build with Partanna technology?

Partanna has all the versatility of Portland cement-based concrete, without the environmental drawbacks. Our technology can be used to power large-scale infrastructure projects, seawalls, commercial buildings, homes, roads and pavers. It also has decorative applications.

By controlling the water to cement ratio, properties of ingredients, and ratios of ingredients, Partanna is durable in any environment and is responsive to most specifications.

How have the use and benefits of Partanna been independently verified?

Our carbon-negative building materials have undergone rigorous third-party testing and evaluation, affirming their quality and performance meet U.S. and international building codes.

· International product testing and certification firm Intertek has confirmed that our materials meet the essential ASTM standards applicable to concrete products. Additionally, American Engineering Testing (AET) and Beton Consulting Engineers have conducted independent testing to validate the physical and engineering properties of our materials.

· Furthermore, our materials have successfully been approved and included within the building codes in The Bahamas for structural use, ensuring compliance with local regulations.

In terms of carbon dioxide avoidance and removal capabilities, our materials have been assessed and recognized by some of the world’s foremost experts on carbon removal.

· We are listed on Verra, a global leader in carbon credits standards.

· Researchers from Trent University, a renowned Canadian institution, have tested our materials and have proven and confirmed the CO₂ removal capabilities of Partanna.

· Blue Green Future, LLC, an independent group of economists and climate experts, has reviewed our data and conducted an economic evaluation of the environmental value of Partanna’s technology.

· Moreover, we have achieved UL Greenguard Gold Certification, demonstrating our commitment to meeting strict emission standards for indoor air quality.

How might Partanna concrete contribute to a building's Estidama/ LEED certification?

Currently, using Partanna products can contribute up to 13 points within the LEED Certification System, specifically from the following areas: Sourcing of Raw Materials (1-2 pts), Building Life-Cycle Impact Reduction (1-4 pts), and Construction and Demolition Waste Management (2 pts).

What equipment do you use to produce building materials?

No specialized equipment is required for the production of our carbon-negative building materials. Our manufacturing process can utilize the same equipment commonly used for concrete production.

How does Partanna compare to traditional cement?

Partanna building materials have been proven to be just as durable, affordable and versatile as traditional cement-based building materials and are far superior to them in marine environments.

Our concrete outperforms traditional cement in compressive strength tests without requiring additives, providing the necessary structural integrity for a wide range of construction applications.

Our materials have been proven to meet or exceed all relevant ASTM safety standards. Moreover, our process enables the creation of unique textures and designs, providing architects with greater creative freedom.

How does Partanna compare from a cost perspective?

Partanna building materials are cost-competitive with traditional cement-based materials. Several key factors contribute to Partanna's cost competitiveness, including the utilization of locally-sourced recycled components, reduced processing costs, and the generation of carbon credits.

How does Partanna compare to traditional concrete in terms of strength?

Similar to traditional concrete production, various strengths can be achieved by adjusting the amount of binder as well as the brinewater to binder ratio. Using these techniques, Partanna can meet the typical necessary strengths for concrete applications, which generally range from 100-12,000 psi. The time required for curing is also competitive, with Partanna demonstrating typical 28-day strength requirements in as little as 24 hours.

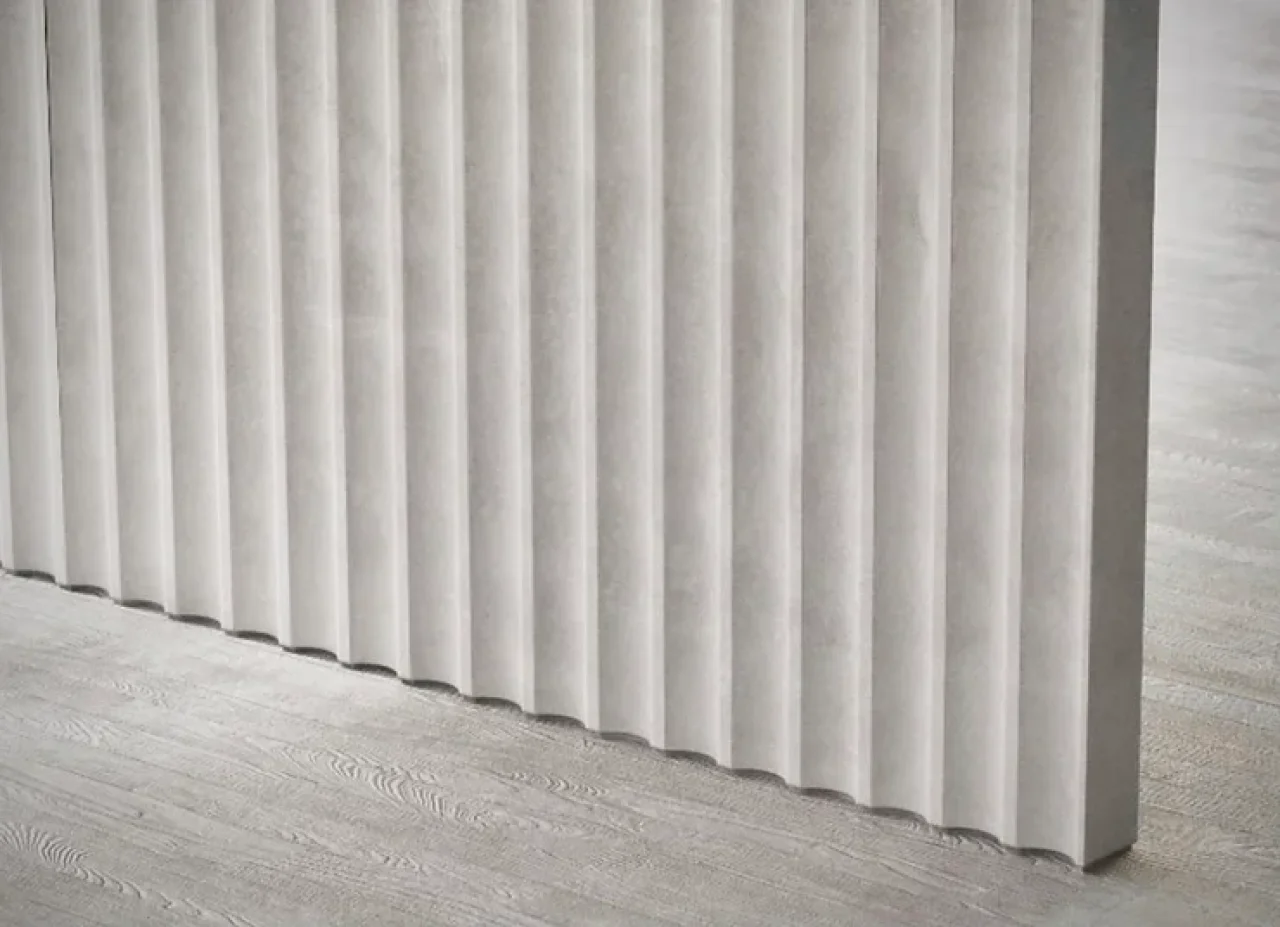

What does Partanna look like?

Our innovative concrete technology enables the creation of unique textures, colors, and designs, providing architects and builders with greater creative freedom in their projects. In its natural state, it is a bright white with a grey tint.

Is Partanna susceptible to a sulfate attack?

The hydraulic nature of our mixture enables it to cure in the presence of water, while the salts in the brine activate reactions that produce stable and alkaline pH-neutral carbonates. This prevents susceptibility to corrasion and sulfate attack and ensures the durability of Partanna concrete.

Is Partanna compatible with rebar / reinforcing steel?

Yes, Partanna is compatible with rebar and reinforcing steel. The introduction of brine initiates an acid-base reaction, forming a stable alkalineand pH-neutral solid. This reaction occurs during curing and subsequent exposure, providing the necessary conditions for the reaction to proceed. The compatibility is maintained due to the hydraulic nature of Partanna cement and the activation of reactions by the salts in the brine, resulting in stable carbonates and protection against corrosion and sulfate attack.

News Hub

April 16th, 2023

What is Grey Carbon?

Rebekkah Swisher, VP of Sustainability at Partanna Global, explains the concept of ‘Grey Carbon’

October 26th, 2023

‘Low-carbon’ and ‘carbon negative’ concrete - are the claims real?

Is there such a thing as carbon negative concrete?

April 16th, 2023

What is Partanna? Q&A with CEO, Rick Fox

Rick Fox, Co-Founder and CEO of Partanna Global, explains the story behind Partanna and its vision for the future.

Pricing & Procurement

(20 Words) Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse accumsan, nunc non iaculis sollicitudin, metus nisl mollis.